Stockouts are every store’s sworn enemy. Between lost sales, frustrated customers, and eroding loyalty, there’s nothing, absolutely nothing, good about a stockout. In the USA alone, the cost is estimated in billions per year — a hefty sum, to say the least. So how do we avoid it?

Today, several technologies offer clear, indisputable ways to prevent stockouts from cropping up in stores. Yet putting them in place changes traditional ways of working. How, exactly? Where does the impact show up?

That’s the open question.

These are precisely the questions we wanted to ask and the ones we invite you to explore in this article. And we promise: we’re not short on ideas to point you toward the right strategy!

Reminder: Stockouts, NOSBOS (Not On Shelf But On Stock), and Visual Out-of-Stock-Three Different Realities

Before we dive in, we need to be clear about what we’re talking about and that’s exactly what this section covers. In most people’s minds, a “stockout” means “the product is missing from the shelf.” In practice, though, there are three distinct types of stockouts:

1. The “classic” stockout

The most familiar form of stockout is the “nothing anywhere” scenario. In other words, the product is no longer available either on the shelf or in the backroom. It typically ranges from 1% to 3% of product SKUs. When it happens, it points to a failure to anticipate demand or to an external disruption (supply chain issues such as supplier or transport delays, warehouse stockouts, or even contractual disputes with manufacturers).

2. The NOSBOS (Not On Shelf But On Stock)

This type of stockout has historically been more frequent. It generally affects 2% to 8% of SKUs. Here, the product is available in the backroom but not on the shelf. The issue isn’t supply or a lack of demand forecasting, it’s an in-store execution problem. Causes can include poor priority management, errors in orchestrating restocking runs, or a poorly organized stockroom (the product simply isn’t found).

3. Visual out-of-stock, or the “false” stockout

In this scenario, the product is available on the shelf, but customers aren’t buying it because they don’t see it. For example, the item may be at the back of the shelf, in the wrong location, or hidden behind another SKU. Consequently, this is primarily a merchandising issue (signage and planogram management).

With these definitions in place, let’s move on to the core of our topic.

Impacts of New Technologies on Traditional Methods: From Correction to Prevention

Efforts to curb stockouts traditionally focus on three levers: recording stockouts, maintaining accurate and well-organized inventory, and finely forecasting demand to optimize shelf space. Today, however, each of these practices is being reshaped, one way or another, by the arrival of new in-store technologies. Let’s take stock.

1 - Are Stockout Audits on the Way Out?

Could the tedious morning stockout check soon become a thing of the past? If we go by the new technologies on the market, the question is fair.

Today, to gauge the level of stockouts, regular checks are necessary. And to properly analyze their root causes, those checks need to be done in the morning before opening or the night before — even when “there’s no time.”

That could be about to change.

With new technologies like Captana from Vusion Group or Hanshow, stockouts can be anticipated, limiting the need for repetitive, time-consuming corrective actions. Using small wireless cameras or robots, these solutions determine shelf capacity and on-hand stock for each SKU. Combined with an analysis of sales velocity, it becomes easy to flag potential stockout risks for a given item. All that’s left is to run the necessary restocking rounds. Result: stockouts 0, you 1.

And if stockouts still occur, a morning report provides a one-glance view of existing issues. No need to walk down every aisle anymore.

A word of caution, though. For this daydream to become reality, alerts must be orchestrated alongside other tasks and priorities. That means knowing who does what, when, and for how long and therefore managing tasks and the time they take. Without structure, things can quickly go off the rails.

2 - Inventory Reliability: Preventing Stockouts Through Organization and Technological Innovation

Having reliable inventory is fundamental to a store’s performance. Yet today, there’s a glaring lack of accuracy. According to Gartner, inventory accuracy often reaches only 60%. IHL Group reinforces this finding, reporting that more than half of retailers acknowledge accuracy below 80% in their data. [1] In short, the trend needs to be reversed.

Walmart’s IoT: A Substitute for RFID?

Walmart is piloting a massive initiative to integrate ambient, battery-free IoT sensors (powered by radio waves/light) across its supply chain.

This technology-touted as more scalable and less expensive than RFID-aims to deliver real-time inventory accuracy on millions of pallets and to feed the company’s AI infrastructure with precise location, temperature, and humidity data.

The end goal is to fight inventory distortion (both stockouts and overstocks), a costly problem for the sector. [1] If the innovation lives up to its promise, it could, in theory, make inventory-reliability tasks far less tedious. To be continued…

[1] Retail.wire.com

The Often-Forgotten Basic: A Well-Organized Backroom to Prevent Stockouts

While technological innovation is advancing (as Walmart’s example shows), the foundation of readable, reliable inventory still starts with a well-organized backroom. Yet this space is often the least orderly—leading to two major errors:

1. False stockouts:

Your replenishment system shows on-hand backroom stock for an item that’s out of stock on the shelf. Yet you can’t find it—not because the system is wrong, but simply because the backroom is poorly organized. The consequence? You unnecessarily adjust your inventory parameters and potentially create overstock or even record an unjustified “unknown shrink.”

2. Operational delays and missed sales:

A product that’s hard to access (requiring other cases to be moved) delays the restocking run that needs to happen. That simple delay gives a customer time to come by and not find the item—turning a preventable stockout into a lost sale. The stakes are twofold: ensure inventory accuracy and make sure the restocking happens on time. That requires dedicated time for organizing the backroom.

To that end, with TimeSkipper, tasks like “backroom organizing,” as well as “negative inventory checks” and “anomaly analysis and handling,” are no longer done “when we have time.” They’re integrated directly into your store activity plan without compromising other tasks and priorities thanks to workload calculations that let you see available time at a glance.

3 - Better Demand Forecasting in Service of More Flexible Shelf Space?

Preventing stockouts – especially total stockouts – still starts with anticipating demand. And to do that well, new technologies are stepping up. Predictive algorithms based on historical patterns or real-time consumption analysis help you anticipate either a temporary spike in demand or a broader, longer-term increase.

Walmart (yes, it again) has even gone a step further by equipping its merchants with an AI agent called “Wally.” Its goal is to automate strategic assortment analysis. It excels at demand forecasting and shelf optimization, ensuring the right products are ordered in the right quantities at the right time. It also identifies the root cause of total stockouts (supplier issues, logistics, or faulty forecasting).

With more precise demand anticipation and modern shelf-optimization techniques, we can start envisioning more flexible shelf space. By adjusting a product’s facing capacity based on expected sales, you can more easily drive incremental purchases and therefore additional revenue. However, that also implies more tasks tied to shelf management, which will need to be properly orchestrated. The same goes for the continuous adjustment of replenishment-system parameters, which will need to be (re)updated.

Going Further: How to Orchestrate New Technologies and Traditional Methods?

We’ve just seen that stores are better equipped than ever to spot stockouts before they happen. However, not all of the tasks that prevent them are destined to be automated. The challenge, then, is to build a flexible organization that can handle alerts while ensuring that tasks tied to more traditional methods still get done. Here’s the approach we recommend.

1- The Need to Turn Every Alert into Actionable Tasks

Many alerts fail to trigger immediate action — not out of bad intent, but due to a lack of flexibility and operational materialization. If a “likely stockout” alert doesn’t become a clear task time-stamped, with a duration, an owner, a priority order, and a realistic slot in the day, it gets lost in the noise. Between prediction and full shelves, the “last hundred meters” of execution are missing.

2 - Moving from Data to “Data Action”

To get through the “last hundred meters,” three simple things are required:

- Translate each alert into a concrete task.

- Insert these “data actions” into the team schedule in real time.

- Arbitrate fairly when everything hits at once.

And that’s exactly what TimeSkipper enables you to do.

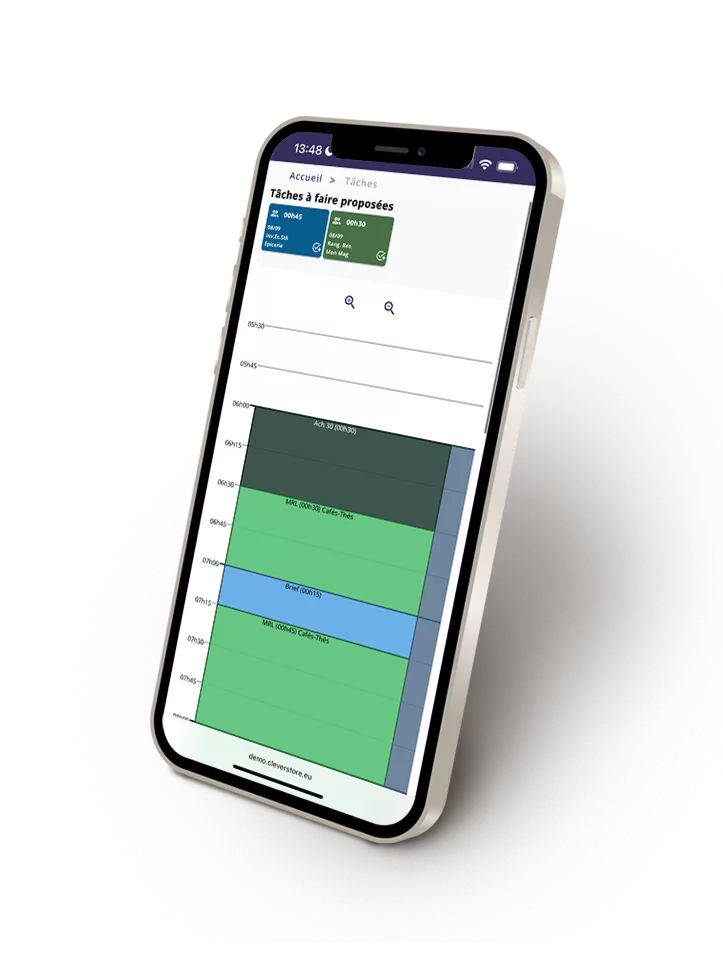

Now available on mobile, our solution helps you orchestrate all these “data actions” without cutting into other store tasks and priorities. For example, an alert about a future product stockout automatically generates a restocking task that the manager can assign to an associate in real time. Of course, they arbitrate based on each person’s available time. They can also choose to place it in a shared pool: the first associate to self-assign the task handles it — building accountability and autonomy within the team’s task management.

Data alone doesn’t create value. It’s the rapid conversion of data into action that makes the difference. By orchestrating data-driven tasks and using mobility as a driver of responsiveness, TimeSkipper ensures every piece of information is acted on efficiently in the field.

What Should You Remember?

New technologies are already changing how work gets done in stores. Some tasks will disappear, others won’t. To orchestrate everything without leaving anything to chance, managing the workload to be done is the first step.