In recent years, the rise of drive-in food retail has been a genuine growth factor for points of sale, but it does not cost them any less! Indeed, the staff costs linked to preparing and delivering orders are high, and there’s no way this cost can be billed to the final customer. This is a major blow to profitability!

The answer to this economic model’s fragility lies in the ability to synchronise order preparation with the time slots dedicated to making products available to customers (slotting) while respecting the promise to have ordered items delivered on time. To achieve this, it’s essential to manage the workload correctly and guarantee an optimal employee occupancy rate. We’re talking about task management… the trick is to know how to do it when it comes to drive-in activities!

Timeskipper presents its new feature dedicated to forecasting and prioritising drive-in tasks to manage your point of sale better.

1. Preparation methods and types of drive-ins: specificities that influence productivity

It’s essential to consider the different types of drive-ins and preparation methods, as their impact on the workload is significant.

Indeed, depending on the brand, the preparation methods may vary:

- Order by order: the picker manages one order at a time.

- Multi-order: the picker carries out several orders at the same time.

- Split orders: several people prepare several orders, but each one is mobilised for a single sector, such as fresh or dry.

The types of drive-ins are also different:

- Picking model: orders are prepared from the warehouse stock.

- Remote model: a warehouse or darkstore is dedicated to stocking the goods provided on the e-commerce site (the number of references is then reduced compared to the point of sale) and preparing and delivering to the customer.

- Hybrid model: a reserve of fast-moving products is dedicated to the drive-in, and the rest of the preparation is done in-store.

- Dedicated order preparation platforms: some chains, such as Carrefour, have this type of structure, which ensures the product storage, order preparation (generally with a high level of automation), and delivery to collection points, such as the in-town pedestrianised drive-ins.

To calculate and manage preparation teams’ workload, it’s essential to start by creating a task reference system with average unit times adapted to each drive-in’s particularities.

This way, allocating the right number of people to incoming orders is done fairly and reasonably.

2. Steering the preparation teams: managing in three timescales

Why is the management of drive-in activities so essential?

The challenge is twofold. It’s essential to know how to optimise the load/capacity ratio (occupancy rate) to prevent the order preparation teams from having too little or too much work to do… Why?

In the first case, these unoccupied working hours are costly for the retailer, especially for drive-ins, where the employees do the shopping for the customer.

In the other case, the challenge is to ensure the work overload or open a maximum number of slots depending on the resources available in different departments, which can be used to reinforce the drive-in team…

Maximising the slot openings, specific workload and occupancy rate management makes it possible to increase turnover and contribute to the store’s market share growth.

In this respect, three timescales are to be taken into account:

1. D-3 weeks: sizing order picking teams

This first phase involves calculating the workload related to preparation tasks based on a forecast volume of online orders based on historical data. On the one hand, this volume makes it possible to determine the number of people needed to cover it. On the other hand, it is used to check the capacity in terms of customer order availability slots, considering the number of vehicles that can be accommodated simultaneously and the loading time.

2. D-1: planning for the next day

At this stage, there’s a stock of actual orders (to be prepared the next day) and a fixed number of planned employees.

From this information, tasks are assigned to the pickers taking into account two elements:

- The calculated workload matches the overlay of the orders on the initial forecast.

- The occupancy rate of the drive-in team and the possible availability in other departments

The first slot opening adjustments can also be considered, depending on capacity, to maximise the number of potential orders or limit it according to available resources.

3. Day D: dynamic adjustment and workload distribution to the people present

Integrating orders placed by customers in the morning into the schedules for collection on the same day. This completes the workload calculated the day before based on outstanding orders.

There are two possible scenarios:

- If the orders booked on D-1 and the orders on the same day are like the forecast, the calculated workload is identical to the one planned for three weeks. This means that there are enough people available to carry out the tasks, and the number of open slots is consistent with the need.

- If, on the other hand, the total volume of orders for the day is lower than the forecast, the number of people present (except for unforeseen absences) has not changed. This is where dynamic adjustment reveals its full potential.

Indeed, as the workload is recalculated according to the number of orders on the day, it will highlight some of the employee’s availability and open slots to deliver customers, which could have been closed beforehand. The method also works if you need to close slots when preparation and delivery capacity has been reached.

In any case, the occupancy rate is continuously optimised!

3. Timeskipper e-commerce module features

Let’s summarise the method to pilot drive-in activities and precisely adjust the slots:

1. Sizing the teams to cover a forecasted workload:

The strength of the tool is that, based on history and an exact predictive algorithm, it can anticipate the work volume (i.e., the number of orders to be prepared) three weeks in advance and up to D-1, as well as the number of people needed to cover this load. The workload, estimated as order picking time, is allocated per hour at this stage.

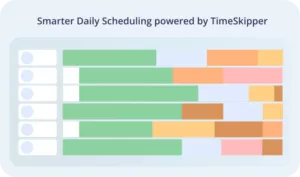

2. Schedule Adjustment according to orders

On D-1, the Timeskipper solution retrieves the outstanding orders and superimposes the actual preparation workload on the forecast. The tool then allocates it to each picker, optimising occupancy rates and slot openings.

On the day itself, the actual load is re-evaluated every quarter of an hour, as orders are placed during the day and allocated per picker, either automatically or by the manager.

Therefore, the Timeskipper e-commerce module fully integrates workload management and slot optimisation. The unit times and the various drive-in tasks can be configured in the tool, depending on the model and structure. It also adapts to method change from an “order by order” model to a “split order by sector” model. In addition, the platform perfectly manages the three timeframes described above, making it possible to plan a load with fixed teams, knowing the actual number of orders, to assign tasks to individuals.

Conclusion

With Timeskipper, you can readjust the workload in real-time and optimise slot openings. And if the ultimate challenge is to achieve 100% slot occupancy and capacity optimisation, you already have a simple lever for managing turnover and profitability!